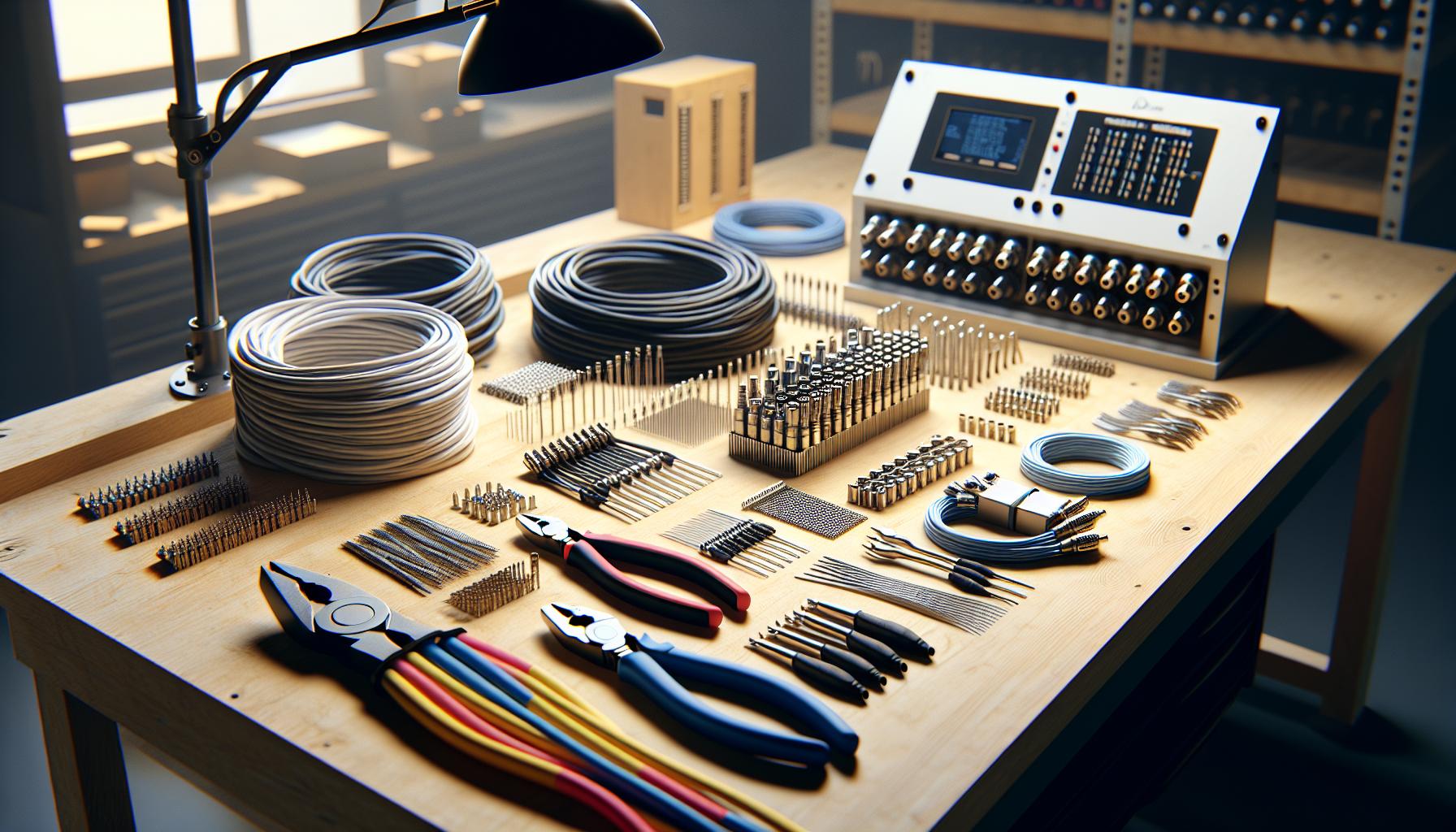

Cable assemblies play a crucial role in connecting and transmitting signals across various electronic devices. Understanding what a cable assembly is and its components can help individuals and businesses make informed decisions regarding design and functionality. This article delves into the essentials of cable assemblies, their applications, and why they matter in today’s tech-driven world.

Understanding Cable Assemblies

Cable assemblies play a crucial role in efficiently connecting and transmitting signals among electronic devices. A thorough comprehension of their structure and applications enhances functionality and design.

Definition of Cable Assembly

A cable assembly consists of an arranged collection of cables and connectors designed to transmit electrical signals or power. This assembly integrates multiple wires, typically insulated, that connect devices, completing circuits essential for operation. Made for specific functions, cable assemblies accommodate varying standards, ensuring compatibility with different electronic components.

Components of Cable Assemblies

Cable assemblies comprise several key components:

- Cables: These conductors, often copper, have insulation that protects against interference and ensures safety. They come in different gauges and configurations based on the application’s requirements.

- Connectors: Connectors facilitate connections between cables and devices. Types include coaxial, USB, and HDMI, each serving unique purposes.

- Heat Shrink Tubing: This protective layer, applied over connections, provides insulation and prevents damage from moisture or physical stress.

- Routing Hardware: Clips or ties may organize cables within an assembly, optimizing space and improving aesthetic organization.

- Shielding: This component minimizes electromagnetic interference, ensuring signal integrity throughout the transmission process. Shielded cables are common in environments with potential interference sources.

Understanding these components aids in selecting the appropriate cable assembly for specific applications, promoting efficiency and reliability in electronic systems.

Types of Cable Assemblies

Understanding the different types of cable assemblies is crucial for selecting the right one for specific applications. Two primary categories exist: custom and standard cable assemblies.

Custom Cable Assemblies

Custom cable assemblies are tailored to meet unique specifications for individual projects. These assemblies incorporate specific components based on dimensions, length, and connector types. Industries often benefit from these assemblies, including aerospace, medical, and automotive sectors. Cloom Tech custom cable assembly solutions provide high-quality, industry-specific designs that ensure durability and precision in high-performance environments. Manufacturers work closely with clients to design these assemblies, ensuring they meet performance requirements and environmental conditions.

Standard Cable Assemblies

Standard cable assemblies utilize common components and configurations suited for a wide range of applications. These assemblies follow industry standards, making them readily available and easily integrated into existing systems. Common uses include telecommunications, consumer electronics, and industrial machinery. Standard cable assemblies offer reliability and efficiency, catering to general consumer needs without the need for customization.

Applications of Cable Assemblies

Cable assemblies serve vital roles across different sectors, ensuring reliable connections and efficient signal transmission.

Industrial Uses

Cable assemblies in industrial settings facilitate machine-to-machine communications, power distribution, and control systems. They connect various components within industrial machinery, such as sensors, actuators, and controllers. These assemblies often utilize robust materials to withstand harsh environments, including temperature fluctuations, moisture, and mechanical stress. Industries like manufacturing, aerospace, and energy rely on cable assemblies for automation, data acquisition, and equipment monitoring, enhancing operational efficiency and safety.

Consumer Electronics

In consumer electronics, cable assemblies are essential for device functionality and user experience. They connect components within products like smartphones, laptops, televisions, and gaming consoles. These assemblies often incorporate connectors that enable easy headphone connection, power supply, and data transfer. Manufacturers design them for both performance and aesthetics, utilizing compact designs to maximize space within devices. Seamless integration of cable assemblies in consumer electronics ensures optimal signal integrity, supports device longevity, and meets user expectations for performance.

Advantages of Using Cable Assemblies

Cable assemblies offer several advantages, making them essential in various applications. Understanding these benefits aids in selecting the right assembly for specific needs.

Enhanced Durability

Enhanced durability characterizes cable assemblies, designed to withstand environmental stressors. Cables and connectors are often made from robust materials that resist abrasion, chemicals, and extreme temperatures. For example, assemblies used in industrial settings typically utilize ruggedized components to ensure longevity, even in harsh conditions. This durability minimizes the risk of damage, thereby reducing maintenance costs and downtime.

Improved Signal Integrity

Improved signal integrity is a critical advantage of cable assemblies. High-quality shielding and properly designed connectors reduce signal loss and electromagnetic interference. For instance, assemblies employed in telecommunications are engineered to maintain optimal signal strength over long distances. Maintaining signal integrity ensures reliable performance in data transmission and enhances the overall effectiveness of electronic systems.

Conclusion

Understanding cable assemblies is essential for anyone involved in electronics. Their role in ensuring reliable connections and signal transmission can’t be overstated. By choosing the right assembly—whether custom or standard—manufacturers can improve the performance and durability of their products.

With applications spanning various industries from aerospace to consumer electronics cable assemblies are integral to modern technology. Their design focuses on efficiency and resilience making them a critical component in achieving optimal functionality. As technology continues to evolve the importance of well-designed cable assemblies will only grow ensuring seamless communication between devices.

Frequently Asked Questions

What is a cable assembly?

A cable assembly is a collection of cables and connectors designed specifically to transmit electrical signals or power between electronic devices. They are crucial for ensuring efficient communication and connectivity within systems.

What are the main components of a cable assembly?

The main components of a cable assembly include cables, connectors, heat shrink tubing, routing hardware, and shielding. Each of these elements works together to enhance the assembly’s functionality and reliability.

What types of cable assemblies are there?

Cable assemblies can be categorized into custom and standard types. Custom assemblies are tailored for specific needs, while standard assemblies use common components that comply with industry norms.

Where are cable assemblies commonly used?

Cable assemblies are used in various sectors, including telecommunications, consumer electronics, industrial machinery, and medical devices. They connect components, facilitating communication and power distribution in these applications.

What advantages do cable assemblies offer?

Cable assemblies provide enhanced durability and improved signal integrity. They are built to withstand harsh conditions and feature high-quality shielding that minimizes signal loss and electromagnetic interference.

How do cable assemblies improve signal integrity?

High-quality shielding and well-designed connectors in cable assemblies reduce signal loss and electromagnetic interference. This ensures reliable performance, especially crucial in data transmission for telecommunications applications.

Can cable assemblies be customized for specific projects?

Yes, custom cable assemblies are designed to meet unique specifications for specific projects, often used in specialized industries like aerospace, medical, and automotive to ensure optimal performance and safety.

What industries benefit from custom cable assemblies?

Industries such as aerospace, medical, and automotive benefit from custom cable assemblies, as these assemblies are tailored to meet specific performance standards and environmental compliance requirements.