Cleaning a circuit board is essential for maintaining its performance and longevity. Dust, grime, and corrosion can hinder functionality and lead to costly repairs. This guide will walk readers through effective cleaning techniques, necessary tools, and safety precautions, ensuring their electronic devices run smoothly and efficiently.

When dealing with delicate electronics, it’s important to understand the right approach for each type of board. For example, OurPcb circuit board products require gentle handling and precise cleaning methods to avoid damaging sensitive components. By using proper tools and methods, users can maintain optimal performance and prolong the lifespan of their devices.

Understanding Circuit Boards

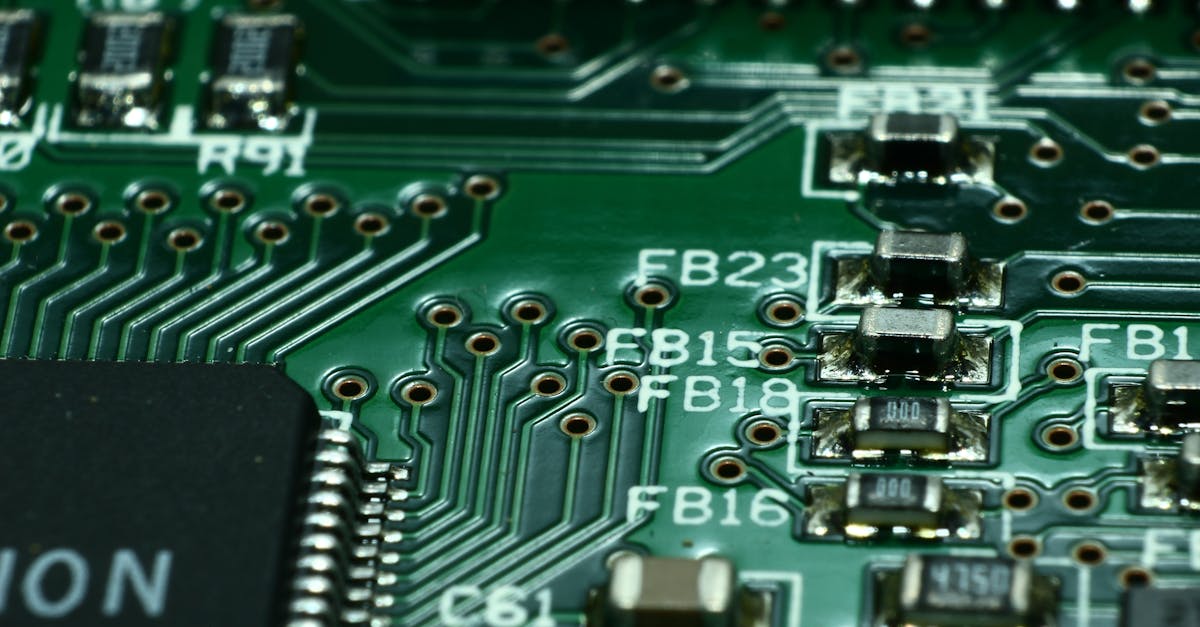

A circuit board, or printed circuit board (PCB), is essential in modern electronics. It serves as a flat, insulating base made from materials like fiberglass, copper, or others. Conductive pathways, known as traces, are etched onto these boards, connecting various electronic components such as resistors and capacitors to facilitate electrical flow.

What Is a Circuit Board?

A circuit board is a key component in electronic devices, including gadgets like smartphones and laptops. Its primary role involves connecting and supporting electronic components, enabling them to function collectively. Typically constructed of non-conductive materials, the board features copper pathways that assist in the transmission of electrical signals.

Importance of Cleaning Circuit Boards

Cleaning circuit boards plays a critical role in maintaining device performance. Dust, grime, and corrosion can hinder functionality and lead to expensive repairs. Routine cleaning extends the lifespan of the device. Effective cleaning techniques, appropriate tools, and safety precautions ensure optimal operation of electronic devices. Regular maintenance reduces the risk of malfunction caused by contaminants.

Preparing for Cleaning

Cleaning a circuit board requires careful preparation to ensure safety and prevent damage. Follow these steps to get ready.

Safety Precautions

- Avoid Water and Moisture: Keep the cleaning area free from water. Prepare the workspace with dry materials, and wear dry clothes to reduce the risk of electrical shock.

- Use Protective Gear: Wear gloves and goggles when handling cleaning agents like isopropyl alcohol to protect against chemical exposure.

- Avoid Scratching: Handle the circuit board carefully. Prevent scratching by using anti-static materials when necessary.

- Screwdriver: Use to disassemble the device and access the circuit board.

- Isopropyl Alcohol: Utilized for cleaning the circuit board, it effectively removes dust and grime without leaving residue.

- Soft Brush: Employ a soft-bristled brush to gently dislodge debris from the circuit board.

- Lint-Free Cloth: Use to wipe the board without leaving fibers that could cause further issues.

- Container: Store screws, cables, and other small parts safely during the disassembly process.

Cleaning Process

Cleaning a circuit board involves several steps to ensure safety and effectiveness. Following these steps leads to better maintenance and improved performance of electronic devices.

Step 1: Power Off the Device

Powering off the device is essential before cleaning. Unplug the device from its power source to prevent electrical shock or damage during cleaning. Ensure all components are inactive, which guarantees a safe cleaning environment.

Step 2: Disassemble the Circuit Board

Disassembling the circuit board allows direct access for cleaning. Use a screwdriver to open the device and carefully disconnect cables. Remove chips or components attached to the board. Document the disassembly process with pictures or notes to assist in reassembly.

Step 3: Choose the Right Cleaning Method

Selecting the appropriate cleaning method is crucial for optimal results.

- Dry Contaminants:

- Compressed Air: Utilize compressed air to eliminate dust and dirt. Spray in short bursts while keeping the canister upright, maintaining a distance of a few centimeters from components.

- Brushing: Employ a small, delicate brush, such as a horsehair paintbrush, to gently remove dirt and dust without damaging the circuits.

- Wet Contaminants:

- Isopropyl Alcohol: Dampen a cotton swab with 90%-100% isopropyl alcohol. Gently brush the swab across areas with grime, ensuring minimal moisture on the board.

Tips for Effective Cleaning

Effective cleaning of a circuit board requires careful execution. Following these guidelines ensures optimal results while maintaining the integrity of the components.

Common Mistakes to Avoid

- Using Water: Water can cause severe damage. Always use dry or isopropyl alcohol methods to clean PCB surfaces.

- Applying Excessive Pressure: Applying too much pressure when brushing can loosen components or damage traces. Use gentle strokes with a soft brush.

- Skipping Disassembly: Jumping straight to cleaning without disassembling the device can lead to incomplete cleaning. Always disassemble the device to access all areas of the circuit board.

- Neglecting Safety Precautions: Failing to wear protective gear puts one at risk. Safety glasses and gloves prevent injuries during cleaning.

- Regular Inspections: Schedule periodic checks for dust and grime accumulation. Regular inspections prevent buildup, maintaining board efficiency.

- Storage Conditions: Store devices in dry, dust-free environments. Proper storage protects circuit boards from environmental contaminants.

- Handling Techniques: Use anti-static wrist straps while handling circuit boards. This minimizes the risk of electrostatic discharge damaging sensitive components.

- Use Appropriate Tools: Opt for a soft brush and high-purity isopropyl alcohol for cleaning. The right tools ensure effective and safe cleaning processes.

Conclusion

Cleaning a circuit board is essential for maintaining its functionality and extending its lifespan. By following the right techniques and using suitable materials like isopropyl alcohol and soft brushes, one can effectively remove contaminants without causing damage. Regular inspections and proper handling further improve the board’s performance.

Taking the time to clean and care for circuit boards ensures they operate efficiently and reliably. By implementing these best practices, individuals can safeguard their electronic devices and enjoy optimal performance for years to come.

Frequently Asked Questions

Why is cleaning circuit boards important?

Cleaning circuit boards is essential for maintaining their performance and longevity. Dust, dirt, and corrosion can hinder the functionality of electronic devices, leading to malfunctions.

What cleaning techniques should I use for circuit boards?

Use isopropyl alcohol and soft brushes for effective cleaning. These methods safely remove contaminants without damaging the delicate components of the circuit board.

How do I clean a circuit board safely?

First, power off the device and disassemble it. Choose the appropriate cleaning method based on the type of contaminants, and always follow safety precautions, such as using anti-static straps.

Should I avoid any specific materials when cleaning circuit boards?

Yes, avoid using water or aggressive solvents, as they can damage the circuit board and its components. Stick to high-purity isopropyl alcohol for best results.

How often should I clean circuit boards?

Regular inspections and cleaning depend on the environment and usage. As a general rule, clean your circuit boards at least once a year or whenever dust and debris accumulate.

Can I clean circuit boards while they are still assembled?

While it’s possible, disassembling the device allows for a more thorough cleaning. It ensures that all areas are accessible and reduces the risk of damaging components.

What tools are necessary for cleaning circuit boards?

Essential tools include soft brushes, high-purity isopropyl alcohol, and anti-static wrist straps. These tools help ensure effective cleaning without causing harm to the circuit board.

How can I store circuit boards to prevent contamination?

Store circuit boards in a cool, dry environment, away from dust and moisture. Use anti-static bags to protect them from static electricity and physical damage.