In the fast-paced world of construction, efficiency is key, and modern brick machines are revolutionizing brick production. These advanced machines streamline processes, reduce labor costs, and improve product quality, making them essential for builders and manufacturers alike. Understanding how these innovations work can provide valuable insights into optimizing production and staying competitive in the industry.

For businesses aiming to enhance their operations, Lontto Brick Machine offers a comprehensive range of cutting-edge brick making equipment. Their selection includes automatic, hydraulic, and mobile brick machines designed to cater to various production capacities and project requirements, ensuring exceptional efficiency and durability.

Overview of Brick Production

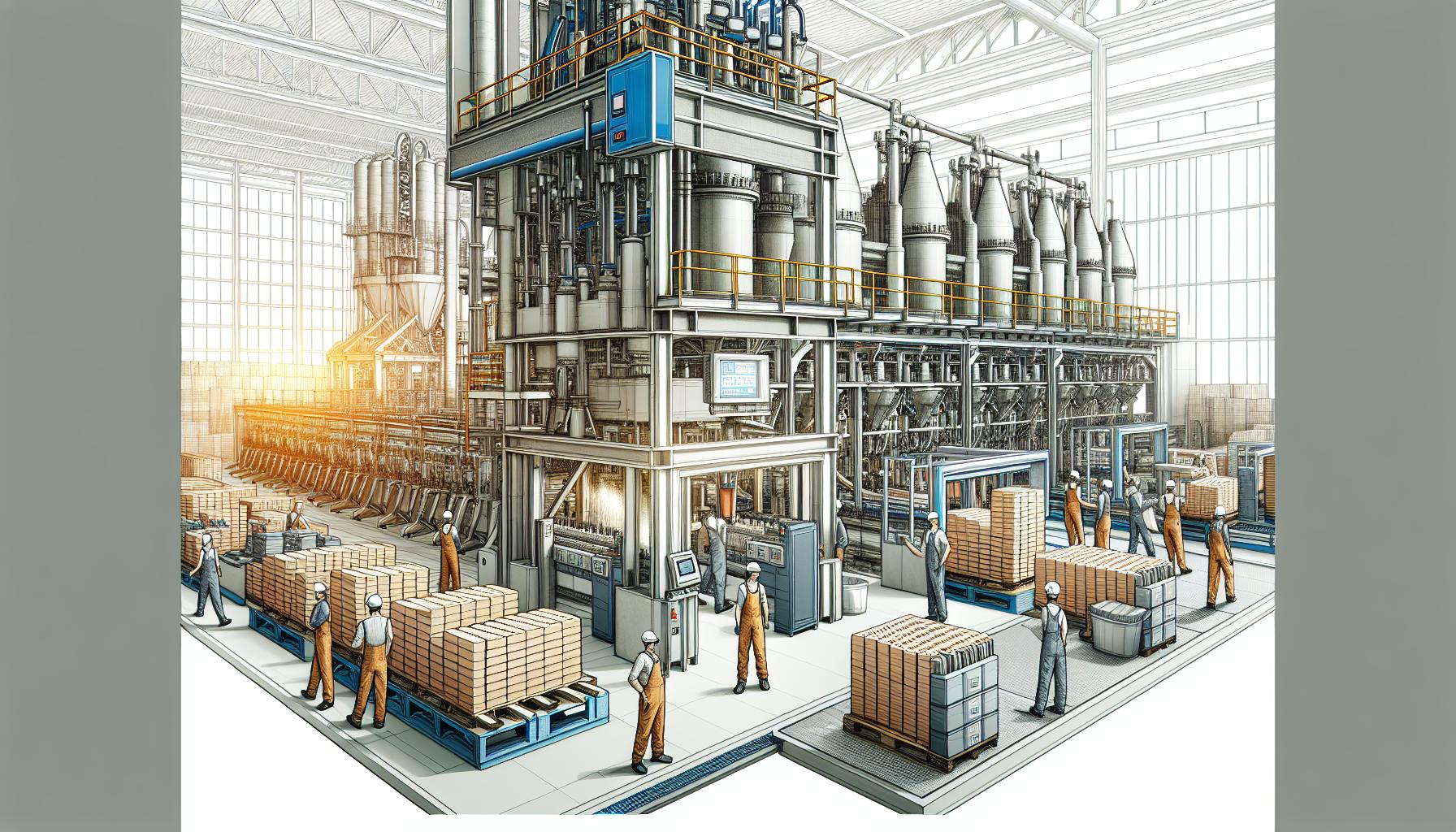

Brick production involves a series of steps to transform raw materials into finished bricks. The process typically begins with sourcing materials, including clay, shale, or other suitable aggregates. These materials undergo preparation, which involves crushing, grinding, and mixing to achieve the desired consistency.

After preparation, the mixture undergoes forming, where it is shaped into brick molds. This step can involve manual methods or modern automated machines that improve speed and accuracy. Once formed, the bricks move to the drying phase, where they lose moisture, reducing the risk of cracking during firing.

Firing follows drying, where bricks are subjected to high temperatures in kilns. This stage vitrifies the clay, providing structural integrity. The firing temperature affects the final product’s strength and durability, typically ranging from 1,900°F to 2,300°F.

Finally, the bricks undergo cooling before packaging and distribution. Modern machines have streamlined this process, improving efficiency and reducing labor costs. Automated systems monitor production phases, ensuring consistent quality and optimizing resource usage. These advancements lead to increased output and enhanced competitiveness in the brick manufacturing industry.

Evolution of Brick Machines

Modern brick machines have transformed the brick production landscape significantly. They optimize the manufacturing process, resulting in higher efficiency and reduced costs.

Historical Context

Historically, brick production relied on manual labor and simple hand tools. Early methods involved mixing clay, molding the bricks by hand, and firing them in primitive kilns. The process was labor-intensive, often leading to inconsistencies in brick quality and production rates. With the Industrial Major change in the 18th century, machinery began to play a role, introducing steam-powered equipment that gradually improved efficiency and consistency.

Technological Advancements

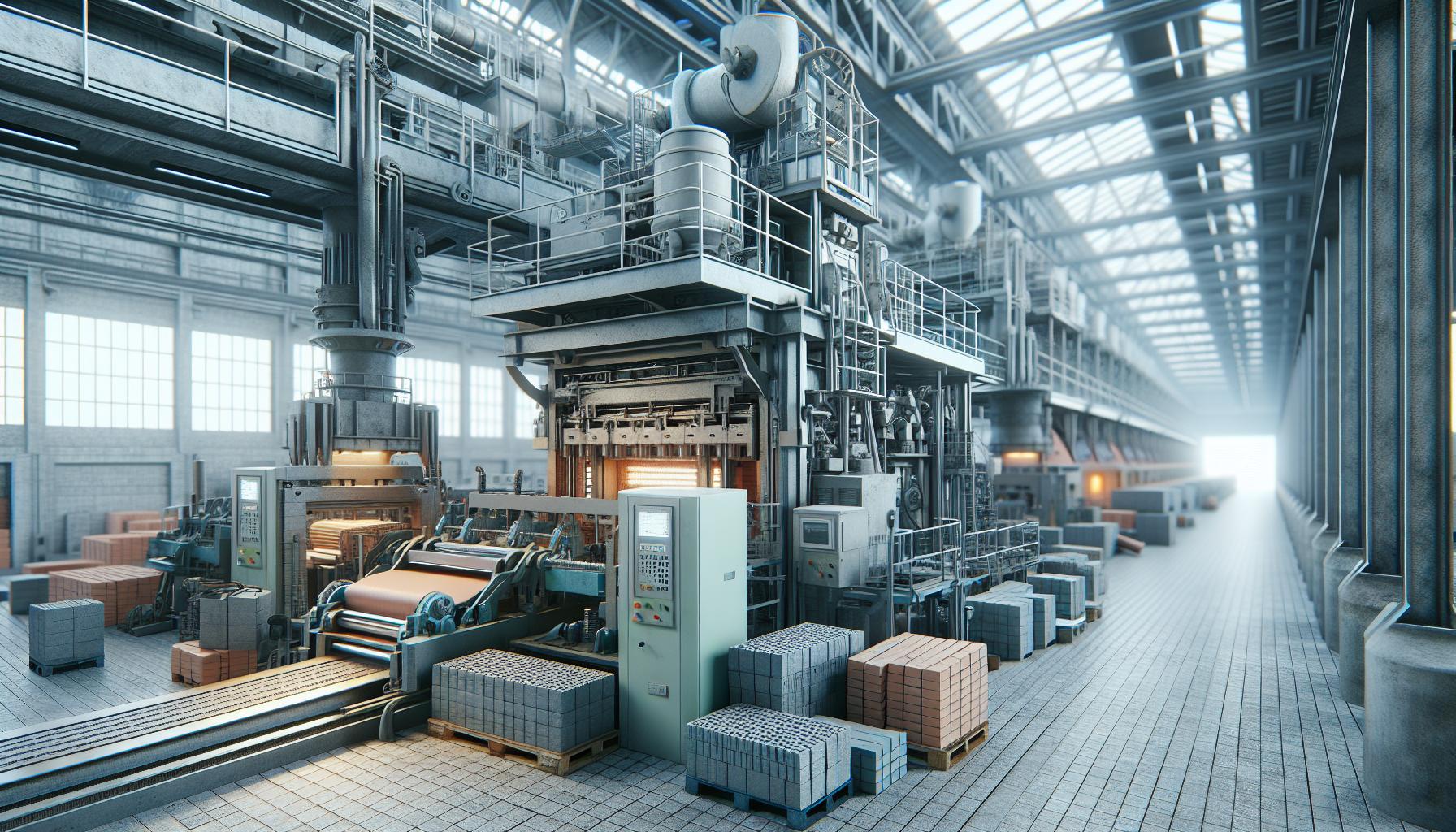

Technological advancements have played a crucial role in modernizing brick machines. Innovations include:

- Automated Mixing Systems: Automated mixers ensure uniform consistency in clay mixtures, reducing human error and enhancing product quality.

- Hydraulic Presses: Hydraulic presses shape bricks with precise pressure, increasing density and strength compared to traditional methods.

- Kiln Technology: Modern kilns use controlled environments with precise temperature monitoring, ensuring optimal firing conditions and improved strength.

- Robotics and AI: Robotics streamline handling and packaging processes, minimizing labor costs and enhancing production speed.

These advancements contribute to a more efficient brick production process, allowing manufacturers to meet growing demands while maintaining high standards of quality.

Key Features of Modern Brick Machines

Modern brick machines incorporate advanced technologies that improve efficiency and productivity in brick production. These machines streamline operations, reduce labor costs, and consistently deliver high-quality bricks.

Automation and Robotics

Automation and robotics play pivotal roles in modern brick manufacturing. Automated mixing systems ensure consistent clay blends, which enhances product quality. Hydraulic presses shape bricks accurately, reducing inconsistencies. Robotic arms efficiently manage the handling and packaging of bricks, minimizing the risk of damage and speeding up the process. These technologies significantly lower the reliance on manual labor, streamlining workflows and improving overall productivity.

Energy Efficiency

Energy efficiency is a critical feature of modern brick machines. Advanced kiln technologies optimize firing conditions, achieving necessary temperatures with reduced energy consumption. Utilization of renewable energy sources, such as solar or wind, further enhances sustainability. These improvements not only lower operational costs but also contribute to environmentally friendly production processes.

Material Handling and Waste Reduction

Innovations in material handling systems increase the efficiency of raw material usage. Automated transport systems reduce manual handling, leading to quicker transitions between production phases. Advanced sorting and recycling features minimize waste, ensuring optimal use of materials. By enhancing the effectiveness of resource management, modern brick machines support sustainable manufacturing practices while maximizing output.

Benefits of Using Modern Brick Machines

Modern brick machines offer significant advantages that transform brick production efficiency. These machines improve speed, improve product quality, and reduce labor costs, essential for manufacturers aiming to stay competitive.

Increased Production Speed

Modern brick machines automate various stages of production, resulting in quicker output than manual methods. For instance, automated mixing systems blend clay uniformly, while hydraulic presses shape bricks precisely in less time. This swift processing allows manufacturers to meet high demand without compromising quality.

Enhanced Product Quality

Modern brick machines ensure consistent product quality. Automated systems analyze mixtures for optimal composition, reducing variability in bricks. High-precision shaping and advanced kiln technologies maintain proper firing environments, enhancing the strength and durability of the final product. These improvements lead to bricks that perform better in construction applications.

Labor Cost Savings

Labor costs decrease with the implementation of modern brick machines. Automation reduces the need for numerous skilled workers, allowing operators to oversee multiple machines simultaneously. This efficiency not only cuts labor expenses but also allocates human resources to other critical areas of production, further boosting overall operations.

Conclusion

Modern brick machines are revolutionizing the brick production landscape. By streamlining each stage of the manufacturing process they significantly boost efficiency and quality. The integration of automation and robotics not only speeds up production but also ensures consistent results that meet industry standards.

As these machines continue to evolve they enable manufacturers to respond to market demands more effectively while reducing labor costs. This shift towards advanced technology supports sustainable practices and optimizes resource management. Embracing these innovations is essential for any brick manufacturer aiming to thrive in today’s competitive environment.

Frequently Asked Questions

What are modern brick machines?

Modern brick machines are advanced equipment designed to enhance efficiency in brick production. They automate various processes, from mixing clay to shaping and firing bricks, resulting in faster production, improved quality, and reduced labor costs.

How do brick machines improve production efficiency?

Brick machines streamline each phase of the production process, ensuring consistent quality and increased output. Automated systems for mixing and shaping, along with advanced kiln technology, significantly enhance manufacturing speed and precision.

What raw materials are used in brick production?

Brick production primarily uses clay and shale as raw materials. These materials are crushed, mixed, and shaped into molds before being dried and fired in kilns to form sturdy bricks.

How does firing temperature affect brick quality?

The firing temperature plays a crucial role in the strength and durability of bricks. Properly managing the temperature during the firing process ensures that bricks achieve the desired structural integrity and long-lasting quality.

What are the benefits of automation in brick production?

Automation in brick production leads to increased speed, enhanced product quality, and significant labor cost savings. Automated systems ensure consistency in mixtures and optimal firing conditions, leading to stronger bricks and efficient resource management.

How have brick machines evolved over time?

Brick machines have evolved from manual labor and simple tools to advanced automated systems, especially following the Industrial Revolution. Modern machines now feature hydraulic presses, automated mixing, and robotics, drastically improving efficiency and product quality.

What role does robotics play in modern brick machines?

Robotics in modern brick machines aids in automation, especially in handling and packaging processes. Robotic arms reduce damage, speed up operations, and enhance efficiency, allowing operators to oversee multiple production activities.

Why is energy efficiency important in brick manufacturing?

Energy efficiency is vital in brick manufacturing as it reduces operational costs and promotes sustainability. Modern kiln technologies utilize renewable energy sources and optimize firing conditions, resulting in lower energy consumption and waste reduction.

How do modern brick machines contribute to sustainability?

Modern brick machines contribute to sustainability by optimizing resource management, minimizing waste, and reducing energy consumption. By using advanced technologies, manufacturers can lower their carbon footprint while maintaining high production standards.

Who can benefit from using modern brick machines?

Builders and brick manufacturers can significantly benefit from modern brick machines. These machines enhance production efficiency, ensure consistent quality, and lower labor costs—crucial for maintaining competitiveness in the construction industry.